How Is Crumb Rubber Made?

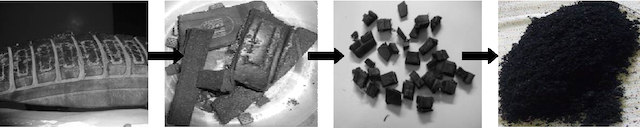

When we hear the word “recycling”, most people think of paper or plastic. Did you know that recycling rubber is great for the environment, too? When rubber is recycled, it’s reduced into crumb rubber, which means small particles of rubber.

Recycling rubber is a pretty interesting process. Read on to find out how it’s done.

Crumb Rubber Is Better For The Environment Than New Rubber

A lot of people don’t realize this, but rubber production is horrible for the environment. The rubber industry is one of the biggest causes of deforestation. Rubber manufacturers keep clearing tropical rainforests to make room for rubber trees. The sad thing is rubber trees don’t even produce that much rubber. In fact, one tree produces only 15-20 pounds of rubber during its entire lifespan. That’s enough for only 8-12 tires.

Not to mention, new rubber comes with a huge carbon footprint too. Rubber is produced in the tropics. This means rubber needs to be brought thousands of miles here to be processed and sold.

Crumb rubber is much “greener” than new rubber in so many different ways. For one, it’s made from used tires and other rubber products. This is a great thing because rubber is not biodegradable. So if you throw out your old tires, for instance, they’ll just sit in the landfill indefinitely. Second, crumb rubber is produced locally, so it has a much smaller carbon footprint.

If you care about the environment, consider buying rubber products made from crumb rubber instead of new rubber. A good example would be a BRIDJIT curb ramp. Each curb ramp is made from 12 passenger tires turned into crumb rubber.

How Do Tire Recycling Companies Acquire Used Tires And Other Rubber Products?

The crumb rubber production process begins with sourcing used rubber. A large percentage of crumb rubber comes from used tires. About 5 out of 6 tires are recycled. Tire recycling companies (or crumb rubber manufacturers) acquire used tires in many different ways. They work with a variety of companies to get used tires. Most commonly:

- Tire shops

- Car dealerships

- Independent shops

Next, the company turns some or all of its tires into crumb rubber. But first, it needs to remove all the steel from the tires.

The Steel Removal Process

Used tires have steel wires in the tire belts and beads. The tire recycling company uses high powered rare earth magnets to separate the steel wires from the tires. This is done in multiple stages to maximize the amount of steel removed and minimize the amount of lost rubber. Some companies lightly shred the rubber first before separating the steel from it.

Sometimes rubber tires have textile reinforcements, too. The company needs to remove those, as well. Often times, the rubber is broken down in various particle sizes after this process. The company still needs to shred the rubber further to ensure evenly sized particles.

Two Of The Most Common Processes For Manufacturing Crumb Rubber

Crumb rubber comes in many different sizes, ranging from 3/8″ pieces to ultra fine particles. There are several different ways to break down rubber into tiny particles. Crumb rubber manufacturing companies typically use one of these two common methods:

- Ambient grinding

- Cryogenic processing

1. Ambient Grinding

This process is the simpler of the two. Here’s how it works:

- The tires go into a raw material chute. The chute contains a shredder, which works much like a paper shredder. The shredder shreds up the tire.

- The chunky tire pieces then go into a fabric separator. This is the step when the rubber is separated from the steel, textiles, fibers, dust, etc.

- The rubber pieces go through a screener. This step ensures that all the foreign particles (steel, textiles, etc.) are separated.

- If there are too many foreign particles, the rubber pieces go through the fabric separator again.

- The rubber pieces are shredded further until they achieve the desired size and uniformity.

- The rubber pieces are packaged up and prepared for shipping.

Some companies produce their own rubber products with their own crumb rubber. Crumb rubber is an ideal material for making rubber mats and such.

2. Cryogenic Processing

Cryogenic processing is a more sophisticated process than ambient grinding. This process uses liquid nitrogen (or a similar material/method) to freeze the rubber particles before reducing their size. This process is done after the foreign materials are separated from the rubber. There are several ways to coat the rubber in liquid nitrogen:

- Freeze the rubber in a tunnel style chamber

- Immerse the rubber in a bath of liquid nitrogen

- Spray the rubber with liquid nitrogen

When the liquid nitrogen freezes the rubber at temperatures below -80°C, the rubber becomes brittle. At this point, the company grinds up the rubber via impact. A hammer mill is the most common impact type reduction process.

This method comes with two major benefits:

- It avoids heat degradation of the rubber

- It produces a high amount of quality rubber that’s free of almost all foreign materials

Do you have any questions about the way crumb rubber is made? Feel free to contact us!